Product Overview

Aquatic Biologists, Inc. takes pride in the high quality of liner material we have available for our clients. PLEASE NOTE: Liners are NOT READY TO SHIP. All liners are CUSTOM fabricated at the time of order. Please allow 10-14 business days for fabrication. Allow additional time for shipping/freight. We will notify you via email when your order was shipped. ALL LINERS OVER 150 LBS. WILL BE SHIPPED VIA FREIGHT. For additional information regarding shipping, please see below.

For liners shipping outside of our normal delivery zone (i.e. AK or HI) - Please call 1-800-442-6648 during our normal business hours to place your order. For additional information regarding shipping please see below.

Benefits of our pond liners include:

- Pliable Forming Material

- Superior Puncture and Tear Resistance

- High UV, Oxidation, and Ozone Resistance

- Fish and plant safe

- NSF-61 Drinking Water Approved!

- Strong HDPE Weaving

- Custom sizing and strengths available: e-mail info@aquaticbiologists.com for a quote

Product Information

ABI’s Reinforced Polyethylene pond liners (RPE Pond Liners) focus on maximum puncture and tear resistance, while ensuring that your liner lasts for years with superior UV resistance.

Our liners are manufactured into a single piece at the factory up to 65,000 sq. ft. to fit your entire pond without the need the attach multiple pieces in the field.

ABI’s RPE Pond Liners are available in standard strength (24 mil single ply) and super-strength (24 mil three ply). In most cases, our standard strength liner will be suitable for the most ponds though some may require a stronger liner. Call to speak with one of our liner specialists if you are thinking you need a super-strength liner.

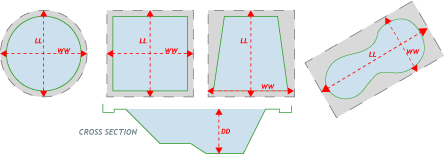

Determine the Size of Your Pond Liner

Below are a few basic examples illustrating how to measure a pond.

If the pond is empty, measure from the anchor trench or shelf down the slope, across the bottom, up to the limit of the trench or shelf in both the widest length and width.

It is always best to measure your pond when it is empty, but at times this might not be possible. If the pond is full, measure your ponds widest width, longest length and deepest depth (in feet). Please note: the pond will need to be drained prior to installing your new pond liner. As such, we recommend draining the pond and verifying your final liner size prior to ordering.

The basic formula to determine the size of your liner is:

Pond Liner Length = Max Pond length + (2 x maximum depth) + 2.5’ for overlap

Pond Liner Width = Max Pond width + (2 x maximum depth) + 2.5’ for overlap

When constructing a larger pond, you may need to use additional liner to securely anchor the liner in place. Additional measurements may also be required. For large ponds consider using 2 - 4 feet of liner on each side. We recommend contacting one of ABI's trained professionals when calculating the liner material required in ponds a 1/3 of an acre or larger.

Installation

Unrolling Your Pond Liner

The liner roll will be marked (typically on the roll itself and on the exterior wrapper) with the length, width and directional arrows.

Example:

This signifies that your bundle will unroll 118’ and then unfold 97’. Position the liner in one corner of your pond so that it will unroll along the length and then unfold across the width. Once the bundle is lying flat along the ground, have all available helpers spread out evenly and pick up the top/leading edge, and pull the liner across the pond 97’. (We recommend having at least one person every 12-16 feet along the edge, to help pull the liner evenly across the pond).

Please note: When panel sizes are larger than 20,000 SF, it is typical to use a beam and spreader bar to lift the roll with a backhoe or other equipment to unroll it.

Once the liner is unrolled and unfolded, try and work out the seams that form. Any seams that are present once the pond is filled with water are considered weak points in the liner.

Sandbags should be placed along the upper edge during installation to prevent wind from turning the liner into a large kite or sail. Enough weight should remain on the liner to prevent it from blowing away but not so much that the liner cannot smooth and conform to the bottom during filling.

Covering the Pond Liner

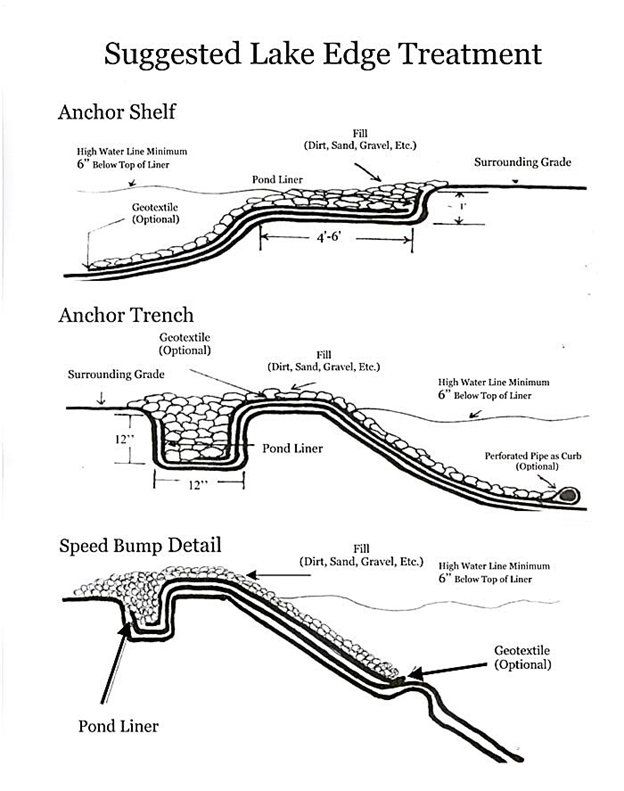

Any exposed edges of the liner should be covered to protect from UV damage. Soil, sand, filter fabric, rip-rap, etc. are all suitable coverings. We have seen it all. Contact one of our specialists to help design your dream shoreline!

Anchoring Your RPE Pond Liner

It is extremely important to anchor your RPE Pond Liner in place to prevent the liner from sliding down the slope and into the pond. The most common way to anchor the liner is with an "anchor trench,” typically 1 foot wide by 1 foot deep, or larger. The most common variation on the anchor trench is the "anchor shelf or bench.” Rather than going down into the ground, the shelf is a flat horizontal (or slightly canted back) area about 4 feet wide that the liner is laid onto, then buried. This method is more popular as the size of the pond gets larger. It also tends to be a little more "forgiving" when attempting to grow grass right down to the water’s edge. Either method is perfectly acceptable and commonly used. The deeper the pond the larger the anchor trench should be.

Warranty Information

ABI’s RPE Pond Liners are manufacturer warranted to be free of material defects for up to 25 years (coverage length determined by liner thickness). This includes the ability of the liner to withstand normal weathering and environmental degradation. The warranty does not cover damage resulting from catastrophic natural events (example: earthquake damage), failure to completely cover the liner in its entirety, improper installation or use (examples include: damage by machinery or other equipment, people, animals, ice, or sharp/rough objects in the substrate).

Packaging and Shipping

All liners are custom fabricated at time of order - allow 10-14 business days for fabrication to be completed. In general, liners smaller than 1500 sq. ft. can be shipped UPS while anything larger is shipped via freight truck on a pallet. Someone must be on location to take delivery of orders shipped via freight truck with a means by which to unload the shipment. Keep in mind larger liners can be several thousand pounds. Once completed, shipping of the liner can take up to 7 days depending on destination.

When is the use of a geotextile (under/overlayment) recommended?

Use of over/underlayment is an option and not mandatory in most cases. However, it is popular for many reasons. We know from experience that physical damage (from deer, kids with rocks, mechanical equipment, UV degradation, etc.) most often occurs on the upper edges of the pond liner. Also, an added degree of safety is introduced; the upper edges are made less slippery so kids, dogs, deer, etc. can get out more easily.

An underlayment should be used when the soil underneath contains rocks or gravel. Anything larger than the size of a thumbnail should try and either be removed or covered before placing the liner.

We recommend 8 oz. non-woven geotextile filter fabric however we have seen plenty of successful installs that use old carpeting. Filter fabric should always be placed along the shelf area when rip-rap or rock is used to protect the liner. It can also help to hold sand in beach areas.

Please call 800-442-6648 to speak to one of our specialists if this option is something you are considering.

*Data and material comparison information has been provided by the manufacturer and ABI experienced staff.